SOLUTIONS FOR INDUSTRY 4.0

DIGITAL CONTROL DEVICES

Real-time control, supervision and data acquisition.

From the simple remote control of the operating parameters of the cooling system to the real-time acquisition of the energy consumption of each component, digital control systems must be able to manage data quickly and accurately, thanks to solutions that are increasingly efficient capable of integrating with the company. infrastructure, in line with the needs of the new Industry 4.0.

What is a digital control device?

EVERYTHING UNDER CONTROL

Digital control devices can be of 2 types:

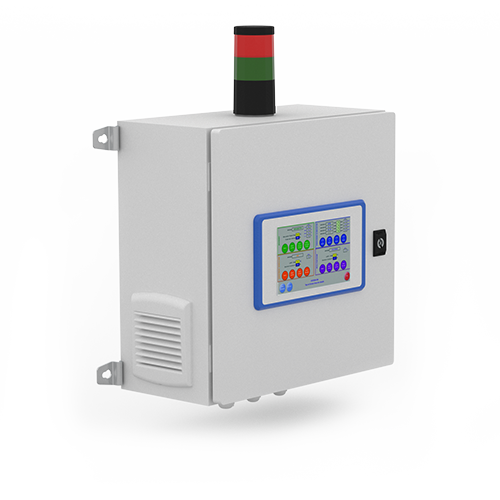

1. Remote control panel: allows remote control of all the parameters of the centralized refrigeration system, such as temperatures, flows, pressures, consumption, etc. In addition, it can manage the system components (compressors, fans, pumps, etc.) according to the programmed control logics.

2. Digital supervision system: it is a digital integration platform for the whole factory. It allows communication, through the serial link, with all plants (localized and centralized), ensuring remote supervision and acquisition of all data.

HOW DOES THE DIGITAL CONTROL DEVICE WORK?

The control panel allows the operator to monitor the operating parameters and alarms of each component. In addition, it can be connected to an external monitoring system and allow, in real time and at any distance, the remote intervention of technical assistance .

The digital supervision system guarantees remote access to the cooling system and allows the supervision and acquisition of operating parameters, consumption and any preventive maintenance of all components, both localized and centralized. Therefore, it allows the optimization of the operating parameters of the systems, increasing performance and energy efficiency.

You want to know more?