Con más de 70 años en el sector de la refrigeración, nuestra filosofía siempre ha sido dar el mejor servicio y trato a nuestros clientes

INFORMACIÓN

Reduces 95% of water and saves 95% in maintenance costs

Frigel’s Ecodry adiabatic cooling system compared to evaporative cooling towers :

· Reduces water consumption up to 95% and energy consumption up to 40%

· Provides greater efficiency in heat transfer

· Reduce maintenance costs by up to 95% and operating costs by up to 40%,

· Reduce CO2 (carbon footprint) by up to 40%

· Allows the total absence of polluting chemical agents, as well as Glycol, reducing the risk of emissions by up to 95%

· Drastically reduces the risk of Legionella

· It offers the best results even in the most difficult weather conditions.

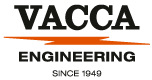

It has 2 working modes:

During most of the year, the unit works as a conventional dry cooler, without water consumption and the heat carried by the water is dissipated in the ambient air by convection of the air forced by the fans.

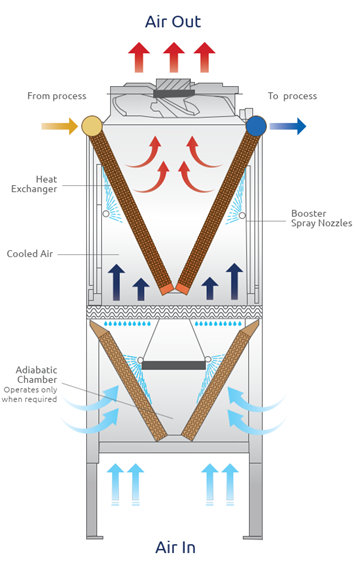

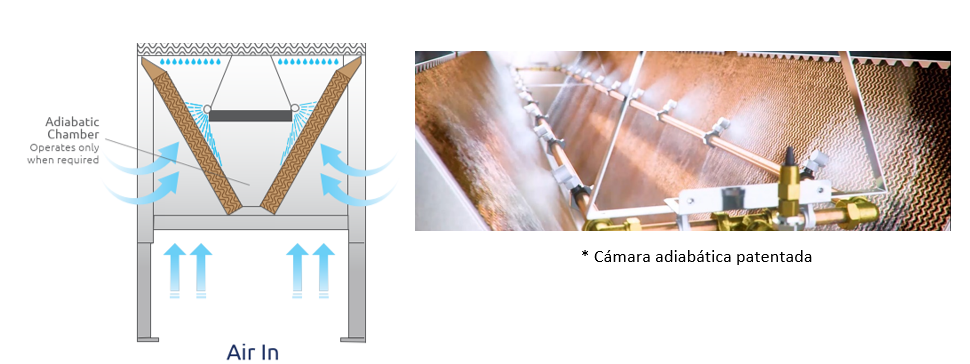

During periods of high ambient temperature and only when dry mode is not sufficient to keep the leaving water temperature within a preset maximum set point, adiabatic mode is automatically activated. The high temperature ambient air, before entering the finned exchanger, passes through the “adiabatic chamber” (patented) where moisture is added and consequently pre-cooled. In this case, the control system continuously regulates the amount of water evaporation, only when necessary, to maintain the desired set point.

Integrated refrigeration systems are synchronized with the processing lines

This means your

Consumption follows real demand: that is, if a production line stops, the

cooling system also shuts down, saving energy and money

while the rest of the factory continues. When demand falls and

production needs to decrease, synchronized cooling works accordingly,

consequently using less energy.

We explain more about the Ecodry 3DK in the following video:

It is a liquid cooler with better performance that implies some advantages such as:

Machinery that allows total control thanks to the following characteristics:

As can be seen in the images, both units contain the panels that will collect the water to later proceed to carry out the corresponding cooling process. The difference is that: the conventional equipment requires much more water because it works by completely soaking it by injection, and then all that water is lost. While the Ecodry system, through its patented adiabatic chamber, carries out a nebulization process to humidify both the air and the panels in parallel, thus optimizing water consumption.

For this reason, Ecodry is unique in the market, being the most ecological and sustainable adiabatic cooler that currently exists, saving not only 95% of water, but also reducing CO2 by up to 40%, as well as operating and maintenance costs. maintenance, thanks to its technology patented exclusively by the Frigel Group.

You want to know more?

Nos encargamos del asesoramiento técnico, diseño, ejecución, legalización y mantenimiento

Con más de 70 años en el sector de la refrigeración, nuestra filosofía siempre ha sido dar el mejor servicio y trato a nuestros clientes

INFORMACIÓN

© Vacca Engineering 2020 | Aviso legal | Política de cookies