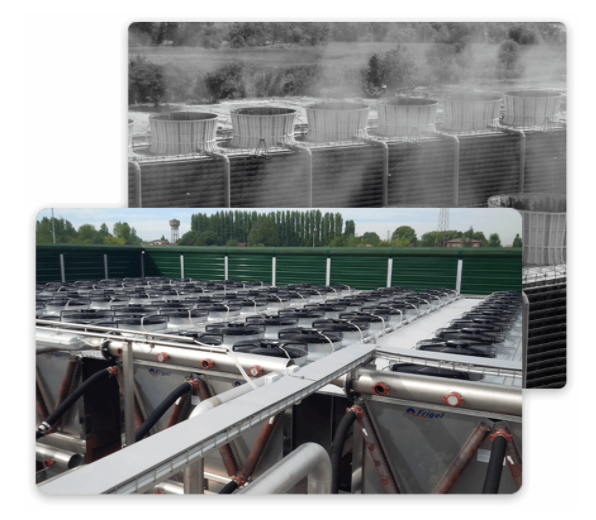

David against Goliath and the Ecodry against the Cooling Tower: a death foretold?

TWe all know the mythical story of David and Goliath, but what if Goliath never had a chance to win? Malcolm Gladwell, famous author of “The Key to Success”, he explains in his talk at TED Conferences that all Goliaths have significant weaknesses that an experienced enemy can discover and exploit, allowing him to come out on top.

Cooling towers, for a long time, have been that giant that seemed impossible to defeat because it was indispensable.

for cooling processes, even if this meant: thousands of liters of water used, chemical treatment required, risk of legionella, CO2 emissions and much more. However, thanks to the Ecodry of Frigel Group (our David), we can carry out refrigeration processes saving up to 95% of water, reducing the carbon footprint by 40% and the risk of emissions by 95%, since we do not

requires chemicals for water treatment. In addition, it reduces operating and maintenance expenses. That being the case, do you know who beat who in the installation in the previous photo? Here’s a little hint:

What is the conventional water cooling tower and how does it work?

The cooling towers are

based on the principle of evaporative cooling, which consists of cooling

large amounts of water dissipating its heat to the ambient air through

from evaporation.

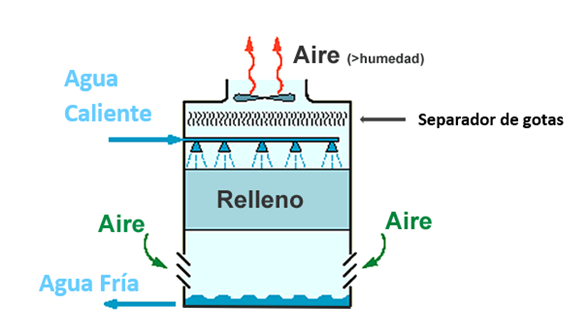

As we can see in the following

scheme, the process is simple:

The process return water inlet enters through the upper part of the tower and this is the one that must be cooled. To do this, it falls through diffusers that spray it in the form of raindrops on an exchanger filling material made of PVC and placed in a specific way. In turn, the air enters through the lower openings, circulating from bottom to top and going through the tower in the opposite direction to the water, until it reaches the upper outlet. During this process in which the water falls (at a higher temperature) and the air rises (at a lower temperature), heat transfer or thermal exchange occurs when both fluids converge. This is when some of the water evaporates, absorbing the energy around it and thus cooling down. The already refrigerated water goes to a lower pool for later use.

The pThe problem with the evaporation of water in the air is that some of that water is lost. In other words, the volume of water that reaches the basin is less than the volume that entered through the diffusers and was sprayed. For this reason, and because they require continuous replacement, cooling towers consume so many liters of water.

On the other hand, stagnation in the lower pool can cause a high risk of Legionella. In order to avoid this, it is necessary to invest not only in machinery maintenance, increasing costs, but also in chemical treatments that damage the ozone layer.

What is the Ecodry adiabatic cooler and how does it work?

The patented adiabatic cooler Ecodry 3DK is a centralized closed loop adiabatic cooling system designed to replace older evaporative cooling tower technology. Installed outside the system, it eliminates the heat extracted from the process, achieving:

- Less water consumption, greater energy efficiency

- M inimizes the risk of legionella outbreaks

- Exceptional operating cost savings, resulting in a low total cost of ownership

- New standards in terms of Environmental Impact, both in terms of ecological footprint and total emissions

- Robustness and reliability of the system, designed for production areas where it is intended to avoid production stoppages at all costs.

How the Ecodry system performs adiabatic cooling

Dry work: The Ecodry system takes advantage of heat transfer by convection to transport thermal energy from point A to point B, taking into account that the transfer happens from the body with the highest temperature to the one with the lowest temperature. Thanks to the use of fans, forced convection is obtained, to generate movement in the fluid from the hot zone to the cold zone, allowing the water temperature to be lowered 5 degrees above the ambient temperature.

In the event that the outside temperature is unfavorable, well above the desired temperature set point, the unit will work in adiabatic mode and its operation is as follows:

- The dry air as it passes through the Ecodry passes through the humidification section in which the supply of water is produced by means of steam lances, or wet panels.

- The increase in the level of humidity above the saturation level of the air, added to the circulation of dry air, causes the direct evaporation of microdroplets of liquid water.

- The energy to produce this evaporation is obtained from the air current which, as a consequence, produces its cooling and an increase in humidity.

In this video we explain everything:

Frigel’s adiabatic cooling system is designed to reduce water use by up to 95% , making it a much more efficient and sustainable alternative to traditional cooling towers that, while effective, consume too much water. This patented technology is an ecological solution that provides greater efficiency in heat transfer, greater energy efficiency, reduced maintenance, cost savings and the total absence of polluting chemical agents, taking care of your business and the planet.

At Vacca Engineering we have been offering the best service in industrial refrigeration processes for more than 70 years. If you need more information on how to optimize your production with the Ecodry adiabatic cooler, do not hesitate to contact us!