What is MiND and how it optimizes industrial processes

The Frigel Group has brought many innovative developments to its process cooling solutions for different industrial sectors: chemical, pharmaceutical, food, beverage, PET, automotive, etc.

All of its product lines now include full digital control technology, along with many enhancements to nearly all of its product categories.

MiND is an extraordinary product and its benefits are many. Since we introduced this innovative tool to our customers, we have seen a great impact on their productions, as they can now measure the efficiency and operational consumption of their systems.

Thanks to the data collected by MiND , our customers can easily identify inefficiencies in their cooling process and make adjustments or adaptations to maximize performance and minimize consumption. This is possible through a web-based interface, designed for customers, which gives them the ability to access MiND and view their Frigel and non-Frigel equipment, when communication is possible, at any time and from anywhere. any computer in the building or remotely. We all know that familiarity with your own process and daily performance is the key to your successful operation today. In fact, we have seen clients who were able to make a big difference to their bottom line after implementing MIND, as they finally had a better understanding of what is happening in their factories.

Advantages of MiND digital control

This digital integration platform, together with central HMI and dedicated monitoring software, enables remote access to all of our refrigeration systems . Remote management of all important parameters predicts and simplifies maintenance, allowing performance to be optimized and proactively saving operating costs .

Main advantages

- Maximize performance and minimize consumption

- Proactively optimize the performance of each machine and/or device

- Measure efficiency and operating consumption

- Simplify and speed up service interventions, even remotely

- Possibility of integrating the data collected with the company’s supervision systems.

Main features of MiND

- Remote control and ability to change the settings and working parameters of all machines (in the case of Frigel units with native integration such as Microgel Digital, TDK and RSD-RSM).

- MiND web-based interface Ability to share all data stored in MiND with other company monitoring systems via Modbus TCP/IP protocol

- All data and information from Frigel equipment stored in a local database

- Ability to access all data locally and remotely

- Real-time and historical operating parameters, alarms and event readings always available

- Possibility to download data and graphics (JPG, PNG, SVG or XLSX and CSV)

- Opportunity to enable communications also with non-Frigel equipment such as power meters, Bowmeters and other sensors via Modbus TCP/IP protocol

- Possibility of implementing comparative analyzes of all stored data.

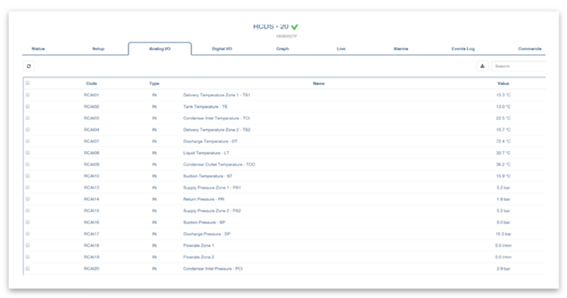

How your control panel works

The Frigel Group In the user interface, there is a dynamic dashboard for each Frigel machine / control system (Microgel, 3PR, Multistage, etc.), where it is possible to observe the status of the machine and the main working parameters updated in real time .

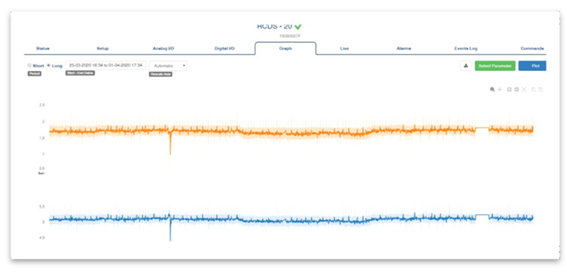

Logs with real-time temperature and pressure list display:

Graph showing parameters for temperature, pressures, warnings, alarms and status changes (parameters on/off mode):

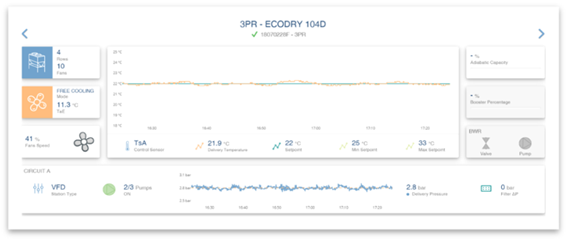

3PR virtual dashboard to display the values of the working conditions of Ecodry and the pumping group, such as:

- setpoint temperature

- Flow temperature

- return temperature

- fan speed

- % Adiabatic / Booster

- Number of pumps in operation.

Application sectors. MiND for your industry

Plastic and Rubber

Process-synchronous cooling: innovation in the plastics industry

- Reduced cool down times

- Better quality of molded components

- Perfect repeatability and reduction of costs and environmental impact.

Food and Beverages

Cooling synchronized with the process. a change of

paradigm in the beverage industry:

- Significant increase in productivity

- Total connectivity and automation

- Perfect repeatability and cost and impact reduction

environmental - Total absence of ammonia.

metals

- Reduction of cycle times

- Reduced running costs with less

consumption of energy, water and maintenance.

Air Compressor Refrigeration

Closed water cycle system, using adiabatic coolers as the most effective, efficient and sustainable cooling solution.

Biogas Energy

Giving value to waste and reducing pollution are great economic and ecological opportunities. Biogas is an energy and economic resource with short-term investments.

Data Centers

The temperatures of the centers

Data varies depending on the servers and the type of data system.

cooling, but temperature fluctuations outside ASHRAE standards

or by design, could have serious consequences for performance. Time

of downtime in data centers is potentially catastrophic and they must

Take every precaution to eliminate, or at least minimize, this

threat.

Gas Turbine - Air Cooling

Maximizes gas turbine power output using a modular adiabatic cooling system built for maximum operating efficiency.

Organic Rankine Cycle (ORC)

cooling solution

Optimized and energy saving for faster payback time. The

ORC is one of the most used solutions to generate electricity from

from low-temperature heat sources.

Electric Network

Effective cooling is

important task to get the most out of the converter station and improve

system reliability.

If you need more information about the MiND digital control or any of the Frigel products, don’t hesitate to contact us! contact us ! Also, from VaccaEngineering We make it easy for you because, if you need it, we carry out the technical study, installation, after-sales service and maintenance of the equipment, offering you a complete “turnkey” service.