Con más de 70 años en el sector de la refrigeración, nuestra filosofía siempre ha sido dar el mejor servicio y trato a nuestros clientes

INFORMACIÓN

UN CAMBIO DE PARADIGMA EN LA INDUSTRIA DE BEBIDAS

Maquinaria para la industria de Bebidas.

Es bien sabido que el enfriamiento tiene un fuerte impacto en el proceso de bebidas.

La productividad, los costos de funcionamiento y el impacto ambiental están, de hecho, fuertemente influenciados por el desempeño de estos sistemas.

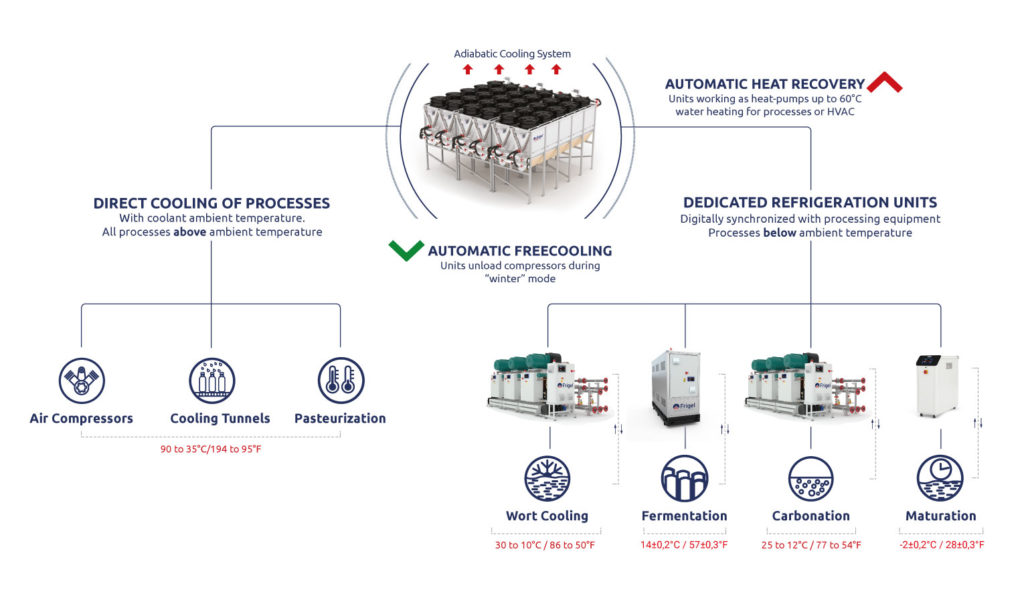

Ecodry System 4.0 es una solución de refrigeración integrada basada en un concepto de ingeniería innovador que representa un cambio de paradigma en la industria de las bebidas.

Solución de refrigeración integrada para la industria de bebidas

Unidades de refrigeración sincronizadas con el proceso

Un enfoque revolucionario que no incluye un sistema de refrigeración para toda la planta de producción, sino unidades de enfriamiento compactas dedicadas a cada línea de proceso.

Cada unidad está diseñada para una aplicación específica, utiliza gas refrigerante de bajo GWP y puede tener circuitos de refrigeración de una etapa (Microgel) o circuitos en cascada de múltiples etapas (MultiStage) con compresores de tornillo accionados por inversor.

Sincronizados digitalmente con la línea de procesamiento (desde la cual se gestiona automáticamente), cada unidad permite buscar y registrar , para cada producto, los mejores parámetros de enfriamiento para maximizar la productividad. Además, los enfriadores de agua pueden enfriarse con agua y usarse como «bombas de calor» para la recuperación de energía.

Sistema de enfriamiento adiabático central

El Sistema Ecodry se completa con una central de refrigeración adiabática colocada en el exterior, para expulsar el calor derivado de los procesos.

Este sistema modular, una alternativa a las torres evaporativas, consta de enfriadores adiabáticos de circuito cerrado que puede mantener la temperatura de enfriamiento incluso más baja que la temperatura ambiente.

Además, este sistema central puede proporcionar enfriamiento directo a todos los demás usuarios que requieren agua a una temperatura superior a la temperatura ambiente, como pasteurizadores, túneles de enfriamiento , compresores de aire, enfriadores refrigerados por agua, etc.

Descubre las nuevas tecnologías de refrigeración para cada campo de aplicación

Sistema de enfriamiento sincronizado con el proceso de producción de bebidas carbonatadas.

Sistema de enfriamiento sincronizado con el proceso para la producción de jugos, bebidas isotónicas y té.

Sistema de enfriamiento sincronizado con el proceso de elaboración.

Las soluciones más eficientes del mercado para cada necesidad de proceso

¿Quieres saber más?

Nos encargamos del asesoramiento técnico, diseño, ejecución, legalización y mantenimiento

Con más de 70 años en el sector de la refrigeración, nuestra filosofía siempre ha sido dar el mejor servicio y trato a nuestros clientes

INFORMACIÓN

© Vacca Engineering 2020 | Aviso legal | Política de cookies

Suscríbete a nuestra newsletter y consigue un descuento de un 2% en los equipos de Vacca Engineering.